Geogrids

Geogrids are characterized by their large opening size. Some geogrids

are made from punched sheets that are drawn to align the polymer

molecules. Other geogrid constructions are formed by welding together

oriented strands or by weaving or knitting yarns and coating them

to form a grid configuration. |

|

|

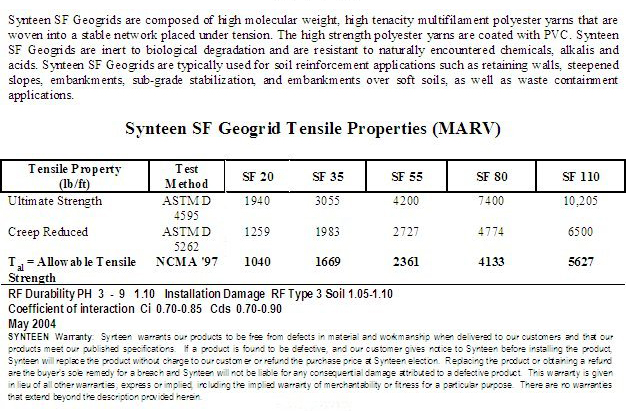

SF

SERIES SOIL REINFORCEMENT GEOGRID

The SF Series Geogrid is composed of high-tenacity multifilament yarns

of high molecular weight polyester that are woven into a stable network

placed in tension. The high strength polyester yarns are coated with

a PVC material. SF Geogrids are inert to biological degradation and

are resistant to naturally encountered chemicals, alkalis and acids.

SF Geogrids are typically used for soil reinforcement applications

such as retaining walls, steepened slopes, embankments, sub-grade

stabilization, embankments over soft soils, and waste containment

applications.

The flexibility in both manufacturing and product selection makes

SF Geogrids "the next generation" of polyester soil enforcement

grids.

The standard geogrids product range, combined with STF's ability to

manufacture specialty site specific geogrids allows the engineer flexibility

in the design of soil reinforcement structures. For example, SF Geogrids

would aid in the design of a void bridging application where tensile

strength requirements are high in both directions of the geogrid.

|

|

INSTALLATION

Installation of SF Geogrid is quick and easy. Because of the product's

light weight and flexibity, no special tools or equipment are required.

Simply, lay out the geogrid, measure it to the required length, and

cut it with a utility knife or scissors. When installed, SF Geogrid

lays flat. It will not recoil, even in cold weather. |

| SYNTEEN

SF SERIES SOIL REINFORCEMENT GEOGRID |

|

| |

PAVEMENT

STRUCTURES

SYNTEEN

BASE COURSE REINFORCEMENT

SUBGRADE

IMPROVEMENT BIAXIAL GEOGRID

SF 11 is

composed of high molecular weight, high tenacity multifilament

polyester yarns that are woven into a stable network placed under

tension. The high strength polyester yarns are coated with a polymer

coating. SF Geogrids are inert to biological degradation and are

resistant to naturally encountered chemicals, alkalis and acids.

SF11 INCREASES

THE SERVICE LIFE OF PAVEMENT STRUCTURES BY IMPROVING:

CONFINEMENT

OF BASE COURSE

- Prevents

lateral spreading of the base or sub-base aggregate

- Allows

for shear interaction to develop between the aggregate and the

geogrid

TENSILE STRENGTH

OF AGGREGATE

1. SF 11

geogrid will reduce applied vertical pressure of heavy loads

at depth of aggregate by spreading the load over a wider area.

SF

11

| REINFORCEMENT

PROPERTIES |

TEST

METHOD |

MARV

VALUES

lbs/ft

kN/m |

| Ultimate

Strength |

MD

XMD |

ASTM-6637 |

2388

3870 |

34.9

56.5 |

| Initial

Modulus |

MD

XMD |

ASTM-6637 |

178,000

172,900 |

2598

2524 |

| Load

at 2% Strain |

MD

XMD |

ASTM-6637 |

526

578 |

7.68

8.43 |

| Load

at 5% Strain |

MD

XMD |

ASTM-6637 |

1042

792 |

15.2

11.5 |

|

True

in place strength after site damage testing based on TRI method

of "installation" damage testing with coarse gravel (GP) and

sandy gravel (SW). |

| Load

at 2% Strain |

MD

(GP)

MD (SW) |

ASTM

6637 + ASTM-5818 |

401

490 |

5.8

6.5 |

| Load

at 2% Strain |

XMD

(GP)

XMD (SW) |

ASTM

6637 + ASTM-5818 |

521

570 |

7.6

8.3 |

| Load

at 5% Strain |

MD

(GP)

MD (SW) |

ASTM

6637 + ASTM-5818 |

795

972 |

11.6

14.1 |

| Load

at 5 % Strain |

XMD

(GP)

XMD (SW) |

ASTM

6637 + ASTM-5818 |

715

781 |

10.4

11.4 |

| Coefficient

of Pullout

Interaction |

|

ASTM-6706

Sandy

Gravel

Sand |

Ci

= 1.0

Ci

= 1.0 |

| Aperture

Size* |

|

Measured |

MD

1.0 in.

XD 1.0

in. |

SF

12

| REINFORCEMENT

PROPERTIES |

TEST

METHOD |

MARV

VALUES

lbs/ft

kN/m |

| Ultimate

Strength |

MD

XMD |

ASTM-6637 |

2388

5268 |

34.9

76.8 |

| Initial

Modulus |

MD

XMD |

ASTM-6637 |

178,000

235,000 |

2598

3432 |

| Load

at 2% Strain |

MD

XMD |

ASTM-6637 |

526

797 |

7.7

11.6 |

| Load

at 5% Strain |

MD

XMD |

ASTM-6637 |

1042

1367 |

15.2

19.9 |

|

True

in place strength after site damage testing based on TRI method

of "installation" damage testing with coarse gravel (GP) and

sandy gravel (SW). |

| Load

at 2% Strain |

MD

(GP)

MD (SW) |

ASTM

6637 + ASTM 5818 |

438

496 |

6.3

7.2 |

| Load

at 2% Strain |

XMD

(GP)

XMD (SW) |

ASTM

6637 + ASTM-5818 |

664

752 |

9.7

11.0 |

| Load

at 5% Strain |

MD

(GP)

MD (SW) |

ASTM

6637 + ASTM-5818 |

868

983 |

12.6

14.3 |

| Load

at 5 % Strain |

XMD

(GP)

XMD (SW) |

ASTM

6637 + ASTM-5818 |

940

1065 |

13.7

15.5 |

| Coefficient

of Pullout Interaction |

|

ASTM

6706

Sandy

Gravel

Sand |

Ci=

1.0

Ci= 1.0 |

|

| Aperture

Size |

|

Measured |

MD

1.0 in.

XD 1.0

in. |

|

|

|

| |

| Phone: 617-965-0007 |

Fax: 617-965-0097 |

| Toll Free: 1-800-770-BOOM |

Email: sales@boomenviro.com |

| |

|

| Factory Location: |

| 1 Coffin Avenue |

| New Bedford, MA 02746 |

| |

| BOOM Environmental Products®is a registered trademark of Geotechnical Supply, Inc. |

|

|

|

|

|

|