|

Waste Water Treatment

One popular method of treating waste water involves storing

it in evaporation ponds or storage ponds. As with other lining

containment applications, the engineering objective is to eliminate

any seepage outside the ponds. Geomembrane liner has accomplished

this objective for the last 30 years.

We have the latest factory fabrication and field installation

technology to insure a first quality project. PVC has been

the dominant polymer in this market due to its ease of installation,

market performance and cost effectiveness.

Tank Linings

Tank Linings

Geomembrane liner is an effective containment membrane used in tanks to hold a

wide variety of liquid - water, wastewater, treated sludge, fuels,

gasoline, etc.

We can manufacture drop-in tank linings for smaller projects to

eliminate any installation costs. We fabricate a wide variety of polymers

in order to be able to select the right material for your project.

Sewage Lagoons

Sewage Lagoons

Many municipalities or industrial facilities rely on aeration to treat,

reduce or eliminate sewage. This aeration will typically take place in a

single or a system of ponds.

Geomembrane liner provides the containment to protect the soil and

groundwater beneath these ponds. Polypropylene is an emerging material

used in this application due to its long term service life and excellent

physical properties.

A Geomembrane liner made from polypropylene provides the following advantages:

- Formulated to provide 20 year service life as an exposed membrane.

- Excellent tensile/tear strength properties provide strength required

in steep ponds of 3:1 slope angle or steeper.

- Easy to field seam and replace; No specialized equipment necessary.

- Not subject to environmental stress cracking as are some HDPE

linings.

- Excellent chemical resistance.

Secondary Containment

Secondary Containment

Impermeable plastic geomembrane liner has been used in many applications for

prevention of seepage, which results in pollution. They are now being used

under oil storage tanks and in diked oil storage areas.

Many states require that provisions be made for containment of oils and

hydrocarbons if the containing vessel should rupture. Plastic geomembrane liner

placed under above-ground tanks or lining diked storage areas provide this

safety feature.

We can design, fabricate and install a containment system

to provide containment if needed while exceeding regulatory requirements.

Whether your project involves fuel, gas or any other hydrocarbons. We

can choose the best material for your project as we work with

many different Polymeric materials.

Reservoirs

Reservoirs

Potable water reservoirs are a crucial element in the treatment system of

many municipalities throughout the world. Many older reservoirs are built

with concrete or asphalt bottoms which have leaked significant volumes of

water costing millions of dollars.

We have provided a solution to this problem for over 30 years. No matter how small or large, easy or complex, we can

install a lining for your reservoir.

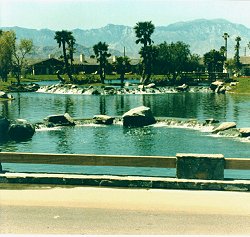

Golf Course Ponds

Golf Course Ponds

Geomembrane liners offer design versatility, easily adapting to the

contours and shapes of your ponds. They prevent water and fertilizer

run-off from seeping into the ground. Flexible materials install

easily and quickly. And, once installed, they're virtually maintenance-free.

When it's time to beautify an add challenge to your course,

the solution is often "just add water".

Aquaculture Ponds

Aquaculture Ponds

Today's sophisticated fish farming procedures demand a more

manageable, controlled environment that can be achieved by

an unpredictable mud-bottom pond. As fish hatcheries respond

to the increased demand for edible fish, synthetic geomembrane liners

are being used for ponds to provide better control, increased production

and decreased maintenance. With the pond bottom not covered with soil, the

pond operator can control the chemical and biological condition

of the pond, and thus reduce chances of disease and other

imbalance in the aquaculture environment.

In addition, synthetic geomembrane liners reduce or eliminate

grass mowing on the side slopes of the pond, stabilize soil

moisture content caused by fluctuating water levels, and reduce

shrink/swell soil instability problems caused by too wet or

to dry soil.

Canals

Canals

PVC linings have been used in North America to contain water in transport

canals since the early 1950's. Initially 10 mil PVC was used for all of

the early projects but was later replaced by 20 mil PVC due to the cost

effectiveness of the material.

PVC is is the material of choice for this

application due to the following factors:

- PVC is provided in large factory fabricated panels to reduce field

seaming requirements.

- PVC is easy to weld in the field.

- PVC is easy to deploy in the field.

- PVC provides long term service life as a containment membrane.

- PVC is a very cost effective material in regards to overall material

cost - resin, sheet, fabricated panel and installation.

The U.S. Bureau of Reclamation (under the Department of the Interior)

and the Province of Alberta have successfully installed millions of square

feet of PVC in their canal systems.

Leakage loss of this water has been eliminated through the use of PVC

linings allowing water to be transported to population areas that do not

have adequate water sources of their own. If you live in these areas, PVC

has been a critical factor in your lifestyle.

Landfill Caps

Just as Federal and State Regulations detail every aspect of landfill

location, construction and operation, they now detail every aspect of its

closure design. A typical MSW landfill cap, from bottom up, consists of

gas-venting layer, a low-permeability barrier layer (soil, a geosynthetic

clay liner and/or a geomembrane), a barrier protection layer and a

vegetable soil layer.

Closure requirements are critical for the post closure life cycle of a

landfill as many landfills do not have synthetic membrane linings to

prevent the filtration of leachate into the groundwater. Consequently the

formation of leachate within a landfill cell must be prevented at all

cost.

PVC

is the primary material of choice for the following reasons:

- Provided in large factory fabricated panels to reduce field seaming

requirements and installation costs.

- Easy seamability-simple field tools required.

- Reliable, durable, fully homogenous factory and field seams.

- Excellent puncture and impact resistance to resist mechanical damage

during installation and earth covering operations.

- "Lay flat" contact subgrade (to promote a complete and

rapid diversion of surface rainwater) as opposed to

"buckling" effect caused in other geomembranes by their

thermal contraction/expansion characteristics.

- Excellent soil friction efficiency.

- Non yield elongation characteristics - PVC will not

"yield" or weaken until it reaches its breaking strength

which occurs at 300-450% ultimate elongation; some geomembrane

materials will yield under continued stress after an elongation of

only 10-12% is achieved.

- PVC is the most flexible of lining materials due to its amorphous

molecular structure.

A specifying engineer or project owner can be assured of the long-term

serviceability of PVC in this application as the product has

been in use for over thirty years as a containment membrane

in various types of lagoons, holding ponds and landfills themselves.

MSW Landfill Linings

MSW Landfill Linings

Throughout history there has always been the need to dispose of the

waste generated by man. Raw sanitary and industrial sewage was emptied

into rivers and lakes. Solid wastes were either incinerated, buried or

deposited in the ocean. When the population of the earth was much smaller

than it is now, these methods provided the most efficient means of

disposal. They were also relatively safe in so far as public health was

concerned as nature was able to safely break down the disease carrying

bacteria and other organic materials and render them harmless. However, as

the population grew the lakes and rivers became so saturated with sewage

that nature was unable to keep purifying the waters and pollution of such

major proportions occurred, that it threatened public health. At the same

time sanitary landfills were being used without regard for water purity,

with the result that pollution found its way into our groundwater causing

many problems ranging across a wide spectrum.

One solution to prevent this pollution was to place a liner within the

landfill. Some of the materials used were clay, bentonite, asphalt and

plastic membrane liners. Since impermeable plastic membranes have been

used successfully for years in preventing seepage of water and various

waste liquids, it was only logical that these be considered for sanitary

landfill use. In addition, they have long life, are highly resistant to

leachate and have the proper mechanical properties to be successful in

this application.

We have supplied and installed containment linings for MSW Landfills

since the 1970's. Federal RCRA Regulations enacted in the mid 1980's has

dramatically increased the demand for landfill linings.

We have worked with various government authorities and industry associations

to adopt QA/QC procedures and specification guidelines. Both

PVC and Polypropylene have been used in this application successfully.

Decorative Ponds and Lakes

Decorative Ponds and Lakes

Decorative ponds and lakes enhance property appearance as well as

increase property values. Natural soils cannot always adequately contain

water and may leave a "murky" look in the pond. Our liners

provide the following features:

- Long term leak-free service life.

- Flexibility to form fit your pond or lake.

- Large fabricated panel capability to eliminate or reduce field

seaming requirements.

- Ease of repair if mechanically damaged.

- Leaves a "clean" appearance in pond or lake - no

"murkiness" from pond or lake bottom.

|