The G2 Grease Guard Rooftop Defense

Systems protect your roofing system from the damaging

effects of corrosive grease, oil, chemicals or fluids

that are discharged during routine manufacturing operations.

Petroleum-based oils, motor oil and hydraulic fluid are

used in numerous types of manufacturing facilities.

Oil- and chemical-laden air is vented from the facility

and deposited onto the roof via exhaust fans or piped

discharge applications. The G2 Grease Guard protects

building owners from costly roof repairs, voided roof

warranties, unnecessary fire hazards and excessive

liability claims. Just a few of the manufacturing

effluents that can substantially damage unprotected roofing

systems are shown below.

|

|

|

Before |

| |

|

After

|

|

|

- Helps you comply with 40 CFR 122.26 (1998) when used as

a Best Management Practice in your Storm Water Pollution

Prevention Plan.

- Prevents costly roof repairs and voided roof warranties

- Reduces fire hazards and excessive liabilities.

- Listed by Underwriters Laboratories Inc. for

effectiveness and safety.

- Helps you comply with OSHA, NFPA and EPA regulations.

|

| Rooftop Defense Systems Work |

|

|

|

Filter Diagram

|

|

|

- Top Pre-Filter - a

pass-thru, noncombustible, self-extinguishing filter

constructed from an open cross section polymer.

- Transfer Layer -

constructed from polyolefin fiber. Designed for quick

transfer of oil-based fluids to the absorption layers, while

repelling rainwater. UV stability protects the

absorption layers from damaging sun rays.

- Advanced Filter

Composite - constructed from an engineered open cell

polyolefin fabric. Over 100 layers of absorbent

microfibers wick and contain oil based fluids, while

repelling rainwater. Absorption capacity is up to 78

fluid ounces per square foot.

|

- Barrier Layer - constructed from a closed cell

polymeric blend that provides a leak proof barrier.

- Bottom Layer - an airflow layer constructed from

an open cross section polymer. This layer supports the

absorption and security layers while allowing air to

circulate throughout the entire filter system.

- Fire Shield - a fire-proof barrier that protects

the roof & building from any potential exhaust system

fire hazard.

|

|

Sizing

|

- Measure the area where grease actually drips, splashes

and sprays (A) around the exhaust equipment. Disregard

any areas where gravity moves the grease (B.)

- Add 30" to length (A) and width (A) from Step 1 to

determine the closest G2 Grease Guard size needed.

- For example, if area (A) is 50" x 58", add

30" to each measurement to get 80" x 88" (C).

Use the 80" x 88" (C) to select a 90" square

unit.

|

|

|

|

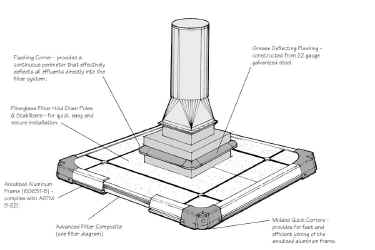

Installation

|

- Assemble the frame around the problem area. The

frame system consists of the patented "Quick

Corners" (A) and the heavy duty aluminum frames (B),

which bolt together using an allen wrench (C) (included) as

shown below.

- Measure and draw the exhaust equipment cut-out area on

the filters. Be sure to measure for a snug fit.

Use scissors to cut the filter materials (D). Once

filter materials are cut, tuck into frame around exhaust

equipment.

- Screw the grease deflecting flashing to the exhaust

equipment curb (E) on all sides. The flashing directs

the grease directly into the absorbent filter system.

|

|

|

|

|

|

Part #

|

Dimensions (LxWxH)

|

Shipping

|

Weight

|

|

| Part #8800 |

48" x 48" x 4" |

Ships in 2 boxes

|

42 lbs.

|

|

| Part #8801 |

60" x 60" x 4" |

Ships in 2 boxes

|

60 lbs.

|

|

| Part #8802 |

72" x 72" x 4" |

Ships in 3 boxes

|

79 lbs.

|

|

| Part #8803 |

72" x 108" x 4" |

Ships in 4 boxes

|

115 lbs.

|

|

| Part #8804 |

90" x 90" x 4" |

Ships in 4 boxes

|

120 lbs.

|

|

| Part #8805 |

108" x 108" x 4" |

Ships in 5 boxes

|

142 lbs.

|

|

| Part #8806 |

120" x 120" x 4" |

Ships in 5 boxes

|

180 lbs.

|

|

| Part #8807 |

144" x 144" x 4" |

Ships in 9 boxes

|

250 lbs.

|

|

|

Other Stock Sizes Available.

|

*COMPLETE SYSTEM INCLUDES: Aluminum frame, Quick

Corners, allen wrench, flashing and screws, Hold-down Grid, top

Pre-filter, Advanced Filter Composite (which consists of Transfer Media,

Absorbent Core, and Polymeric Barrier), Bottom Airflow Filter, Fire

Shield, instructions.

**U.S. Patent Nos. 5,196,040 and 5,318,607.

Other Patents Pending.

|